- info@naffora.com

- 054 911 0885

Naffora International. Trusted Experts in Third-Party Inspection (TPIs).

At Naffora International, we deliver independent Third-Party Inspection (TPI) services that ensure quality, compliance and confidence across every stage of your project.

From pre-inspection meetings (PIMs) to final shipment, our team is actively involved in monitoring fabrication, testing and verification activities, ensuring every detail meets project specifications and international standards.

Our Inspection Scope Includes.

- Mechanical Equipment: Skid Mounted Units, Pressure Vessels, Heat Exchangers, Fabricated Piping, Valves, Control Valves, Pressure Relief Valves etc.

- Structural & Storage Systems: Steel Structures, Tanks, Spheres, Flare Stacks and combustion Systems.

- Pipeline & Coating: Line Pipes, internal and external FBE Coating.

- Electrical & Instrumentation: Complete E&I inspection services as per project specifications,

- Civil Works: Foundations, concrete structures, earthworks and related civil inspections.

Inspection of Skid Mounted equipment.

Built on a single, portable frame, skid mounted equipment integrates piping, valves, instrumentation and control systems into one cohesive unit. This modular design simplifies transport, installation and operation, making it a preferred solution across oil & gas, chemical processing, power generation and water treatment industries.

Our inspection scope includes.

- Chemical Injection Skids

- Metering Skids

- Filtration Skids

- Pumping Skids

- Compressor Skids

- Gas Modular Skids

- Foam Skids

- Fire Fighting Skids

- RO (Reverse Osmosis) Skid Packages

- STP (Sewage Treatment Plant) Skid Packages

Pressure Vessel, Heat Exchanger & Tank Inspection Services.

At Naffora International, we provide expert inspection services for pressure vessels, heat exchangers and industrial tanks. Our certified inspectors ensure every unit meets safety, quality, and performance standards.

What We Do

- Check materials, welding, and dimensions

- Review NDT reports (RT, UT, PT, MT)

- Witness hydrostatic and pneumatic tests

- Verify nameplates, nozzles, and internal parts

- Monitor post-weld heat treatment (PWHT)

- Inspect tanks for corrosion, leaks, and structural integrity

- Examine heat exchangers for fouling, scaling, and tube damage

Standards We Follow

- ASME Section VIII Div. 1 & 2

- API 510, API 650, API 620

- TEMA, API 660

- Project-specific requirements.(Projects Specifications)

Where We Work

We inspect at fabrication shops and during in-service operations—ensuring your equipment is safe, compliant, and ready to perform.

Naffora International, Inspection you can rely on.

Welding Inspection Services

Precision from Root Pass to Final Cap

At Naffora International, we ensure welded joints meet the highest standards of strength, quality, and compliance. Our certified inspectors support critical operations across Oil & Gas, power and infrastructure sectors, where every weld matters.

What We Cover

- WPS/PQR review and welder qualification checks

- Joint preparation and fit-up inspection

- Monitoring of welding parameters (interpass temp, electrode control, sequence)

- Visual inspection and dimensional verification

- NDT validation (RT, UT, MPI, DPI)

- Weld documentation review and repair tracking

- Final weld acceptance based on project specs

Certified Expertise

Our inspectors hold certifications like:

- AWS-CWI

- CSWIP 3.1 / 3.2

- Deep knowledge of ASME Section IX, API 1104, AWS D1.1, ISO 15614

Where We Work

Whether in fabrication shops or on-site field welding, we ensure every weld is defect-free, code-compliant, and built to perform.

Structural Steel Inspection Services

Precision That Supports Every Structure

At Naffora International, we provide comprehensive inspection services for structural steel fabrication and erection. Our certified inspectors ensure that every beam, weld and connection meets international standards and project-specific requirements, supporting safe, durable and compliant construction across oil & gas, power and infrastructure sectors.

Our Inspection Scope Includes:

- Fit-Up & Alignment Checks – Ensuring proper joint preparation and structural positioning

- Welding Oversight – Monitoring WPS/PQR compliance, welder qualifications and welding parameters.

- Visual & Dimensional Inspection – Verifying weld quality and structural tolerances

- NDT Coordination & Review – UT, MT and PT on critical joints and load-bearing connections

- Surface Preparation & Coating Inspection – Assessing blast profiles, paint thickness and corrosion protection as per the project approved paint system.

Standards We Follow

- AWS D1.1

- ASTM etc.

- Project-specific codes and client specifications.

Where We Work

Whether at fabrication yards or construction sites, our inspectors ensure every structural element is built to last safe, compliant and ready to perform.

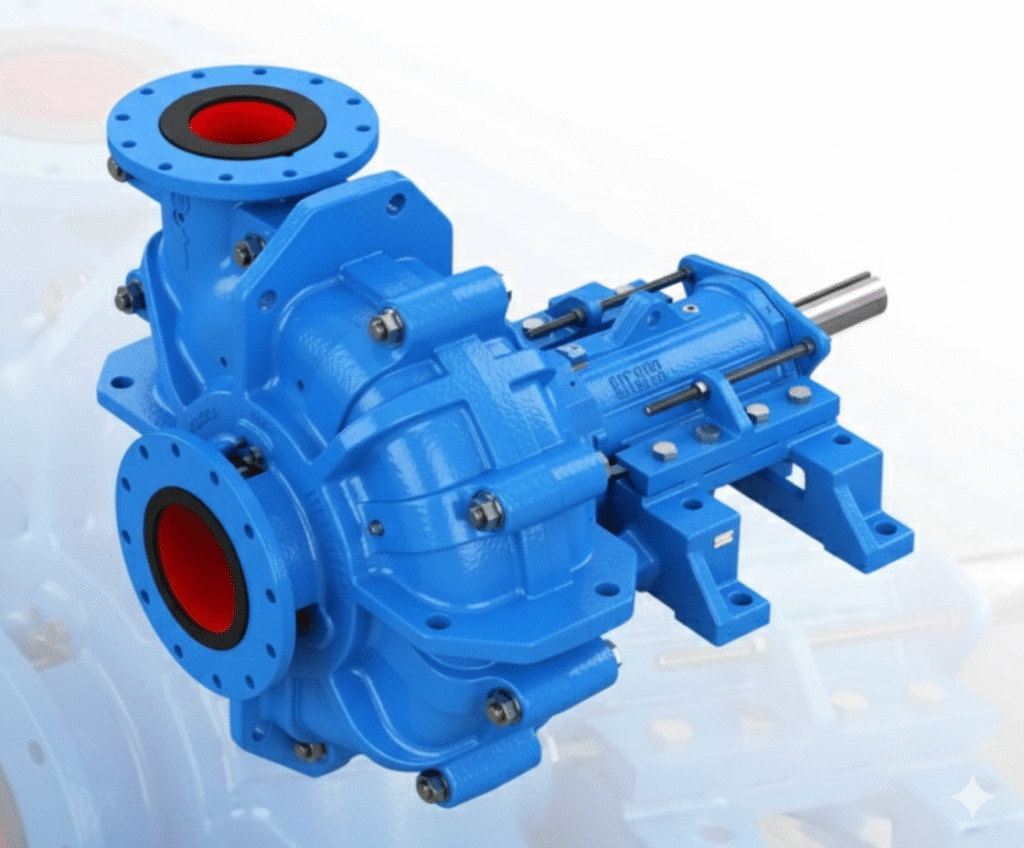

Pump Inspection Services (Oil & Gas Sector).

Ensuring Reliability in Every Rotation

At Naffora International, we deliver specialized inspection services for critical rotating equipment used in oil and gas operations. Our certified inspectors ensure that pumps are built to perform, meeting the highest standards of mechanical integrity, efficiency and compliance before commissioning or shipment.

Equipment We Inspect

- Positive Displacement Pumps

- Centrifugal Pumps

- Reciprocating Pumps

- Screw Pumps

- Gear Pumps

Inspection Scope

- Material verification and dimensional checks

- Assembly and alignment procedure witness

- Clearance validation, rotor balancing, bearing fit checks

- Impeller installation and casing integrity review

- Mechanical run tests and hydrostatic pressure testing

- Performance testing: flow, head, NPSH, power consumption

- Review of QCPs, test procedures, and instrumentation compliance

- Verification of seals, couplings, and accessories against approved drawings

Standards We Follow

- API 610, API 674, API 675, API 676

- ASTM, ASME codes and client-specific project specifications.

All inspection activities are documented with punch lists, NCRs (if applicable) and release notes. Whether at the manufacturer’s facility or during site acceptance, our inspectors ensure pumps are fully functional, compliant and ready for service, minimizing downtime and maximizing reliability in mission critical environments.

Naffora International, Trusted inspection for pumps that power performance.

Crane Inspection Services

Lifting Confidence, Securing Safety

At Naffora International, we provide expert crane inspection services to ensure safe, reliable and compliant lifting operations across industrial sites. Whether for commissioning, third-party certification or routine compliance, our inspections help prevent breakdowns and enhance site safety as agreed in Inspection test plan (ITP).

What We Inspect

- Load test certifications and operational performance

- Functional and safety system checks

- Maintenance records and operator credentials

- Lifting accessories: slings, shackles, hooks

- Critical weld joints and structural integrity

- NDT of load-bearing components (UT, MT, PT)

- Corrosion, fatigue and wear assessment

Standards We Support

- Local and international regulatory requirements.

- Project-specific specifications and safety protocols.

Our inspectors deliver detailed reports, punch lists, and recommendations to ensure your cranes are fit for service and compliant with all safety standards.

Naffora International — Inspection that lifts your standards.

Fabricated Piping Inspection Services

Ensuring Flow with Confidence

At Naffora International, we provide expert inspection services for fabricated piping systems used in critical operations across oil & gas, power and industrial sectors. Our inspectors ensure every pipe, weld and joint meets design codes and client specifications, delivering safety, reliability and performance.

What We Inspect

- Material traceability and spool fabrication

- Fit-up, alignment, root gap, and bevel angle checks

- Welding quality and WPS/PQR compliance

- Welder qualification verification

- Dimensional accuracy and visual inspection

- Non-destructive testing (RT, UT, MPI, DPI)

- Hydrostatic and pneumatic pressure testing

- Coating and corrosion protection inspection

Standards We Follow

- ASME B31.1, B31.3, B31.4, B31.8

- API 570

- Project-specific client requirements.

From fabrication to final testing, our inspections ensure your piping systems are built to last minimizing downtime and maximizing operational integrity within the acceptable tolerance.

Naffora International — Trusted inspection for systems that keep your operations flowing.

Electrical & Instrumentation (E&I) Inspection Services

Precision That Powers Performance

At Naffora International, we offer comprehensive E&I inspection services to ensure electrical and control systems meet project specifications, safety standards and operational reliability. Our inspectors are experienced in verifying installations and functionality across a wide range of industrial applications.

What We Inspect

- Transformers

- Control Panels & Local Control Panels (LCPs)

- Programmable Logic Controllers (PLCs)

- Junction Boxes & Cable Trays

- Wiring & Terminations

- Instrument Function Checks

- Switch gears.

- Factory Acceptance Testing (FAT)

From fabrication to final testing, we ensure every component is installed correctly, functions as intended, and complies with approved drawings and standards. Our inspections help prevent failures, reduce commissioning delays, and support smooth project delivery.

Naffora International — Inspection that keeps your systems connected and compliant.

Inspection of Control, MOVs, On off Valve, PZVs and Manual Valves.

At Naffora International, we provide specialized inspection services for a wide range of industrial valves, including below.

-

Control Valves

-

Manual Valves

-

Pressure Relief Valves (PRVs)

-

Motor Operated Valves (MOVs)

-

On/Off Valves

Our expert-approved inspectors ensure that every valve meets operational, safety and compliance requirements through detailed inspections and testing.

Our Inspection Scope Covers:

-

Material Receiving Inspection

Verification of materials, certifications and compliance with project specifications. -

Non-Destructive Examination (NDE)

Inspection of welds and structural integrity using certified techniques such as UT, RT, MT and PT. -

Positive Material Identification (PMI)

Ensuring the correct material grade and chemical composition of critical components. -

Hydrostatic Testing

High-pressure testing to verify valve integrity and leak resistance. -

Functional Testing

Performance checks for proper actuation, stroke time, response and sealing. -

Painting & Coating Inspection

Surface preparation, paint system validation and DFT (dry film thickness) checks as per specification.

All inspections are carried out in line with international standards such as API, ASME, ISO, and specific client requirements.

With Naffora International, you can rely on thorough, accurate, and fully documented inspections that support the reliability, safety and longevity of your valve systems.

Civil Inspection Services

Built on Precision. Verified for Strength.

At Naffora International, our civil inspection services ensure that structural and foundational works meet design specifications, safety standards, and project requirements. We support infrastructure, industrial and energy projects with thorough inspections at every stage of construction.

What We Inspect

- Concrete pouring and curing processes

- Reinforcement placement and bar bending

- Formwork setup and dimensional checks

- Earthworks, compaction and backfilling

- Anchor bolts, embedded items, and foundation alignment

- Masonry, blockwork, and finishing quality

- Waterproofing, grouting and surface treatments

- Roadwork, paving and drainage systems

Standards We Follow

- International building codes

- Project-specific civil specifications

- Client-approved quality control plans (QCPs)

Our inspectors document every activity with detailed reports, punch lists and compliance records, ensuring your civil works are safe, durable and ready for long-term performance.

Naffora International is your Global Partner for Uncompromising Quality, Safety and Compliance.

Our Services

- Third-Party Inspection (TPIs) Services

- Project Inspections

- Expediting Services

- Supplier/Vendor Assessment.

- Construction Services

Connect With Us

- Al Rawabi, Al Khobar Saudi Arabia

- info@naffora.com

- +966 54 911 0885